Water is the most important nutrient for poultry; survival time is limited in its absence. Birds can survive for longer periods without any other nutrient than they can survive without water.

Although water is regarded as the most essential nutrient, it is impossible to state its exact requirements. Birds generally drink approximately twice as much water as the amount of feed consumed on a weight basis. During periods of extreme heat stress, water requirements may easily quadruple.

Although the importance of providing a sufficient amount of water or adequate access to it is well accepted, the importance of water quality on performance is often overlooked. Water quality attributes can have a direct or indirect effect on performance. High levels of bacterial contaminants, minerals, or other pollutants in drinking water can have detrimental effects on normal physiological properties resulting in inferior performance.

Water quality can be evaluated by a number of criteria. It can be difficult, however, to describe good quality drinking water for poultry because many of the standards have been derived from recommendations for other species of animals or from human standards. In many cases, guidelines have been established based on mortality and not deficiencies in performance. Submitting a water sample annually for analysis should be an important part of good water management. The results of the analysis should be interpreted appropriately to determine the proper course of action. The following are some of the most important factors that influence water quality.

| Table 1. Suitability of Water With Different Concentrations of Total Dissolved Solids (TDS) | |

| TDS (ppm) | Comments |

| Less than 1,000 | These waters should present no serious burden to any class of poultry. |

| 1,000 to 2,999 | These waters should be satisfactory for all classes of poultry. They may cause watery droppings (especially at higher levels) but should not affect health or performance. |

| 3,000 to 4,999 | These are poor waters for poultry, often causing watery droppings, increased mortality, and decreased growth. |

| 5,000 to 6,999 | These are not acceptable waters for poultry and almost always cause some type of problem, especially at the upper limits, where decreased growth and production or increased mortality probably will occur. |

| 7,000 to 10,000 | These waters are unfit for poultry but may be suitable for other livestock. |

| More than 10,000 | These waters should not be used for any livestock or poultry. |

| SOURCE: National Research Council, 1974. Nutrients and Toxic Substances in Water for Livestock and Poultry, National Academy of Sciences, Washington, DC. | |

Mineral Contaminants

A wide variety of minerals are commonly found in drinking water. Normally, they are found in relatively low concentrations and cause no harm (Table 2).

Naturally occurring chemicals

| Contaminant or characteristic | Maximum Contaminant Level | Performance / Plumbing Concerns | Remarks |

| Total bacteria | 0/ml | 100/ml | 0/ml is desirable. |

| Coliform bacteria | 0/ml | 50/ml | 0/ml is desirable. |

| pH | 6.8 to 7.4 | —- | A pH of less than 6.0 is not desirable and lower levels may damage plumbing and equipment. Levels below 6.3 may degrade performance. Calcium, magnesium, iron, and manganese will form hard scale with a pH over 7.0 |

| Total hardness | 100 ppm 6 grains | —- | Hardness levels less than 60 are unusually soft; those above 180 are very hard. |

| Calcium | 60 mg/l | —- | Levels as low as 14 mg/l may be detrimental if the sodium level is higher than 50 mg/l. When combined calcium and magnesium levels exceed mg/l 100 then extreme scaling is probable. |

| Chloride | 250 mg/l | —- | |

| Copper | 1.0 mg/l | 1.3 mg/l | Higher levels produce a bad odor and taste. |

| Iron | 0.3 mg/l | 0.3 mg/l | Higher levels produce a bad odor and taste. |

| Lead | 0.015 mg/l | 0.1 mg/l | Higher levels are toxic. Breeder hens and turkeys may be affected at levels lower levels. Will affect reproductive organs. |

| Manganese | 0.05 mg/l | 0.05 mg/l | Higher levels produce a bad odor and taste. |

| Magnesium | 100 mg/l | 100 mg/l | Higher levels have a laxative effect (125+). Levels greater than 50 mg/l may affect performance if the sulfate level is high. When combined calcium and magnesium levels exceed mg/l 100 then extreme scaling is probable. |

| Nitrate | 10 mg/l | 20 mg/1 | Levels from 3 to 20 mg/l may affect performance. |

| Nitrite | 0.4 mg/l | 2 mg/l | Young chicks are extremely vulnerable at levels of 1 mg/l |

| Sodium | 250 mg/l | 250 mg/l | Levels above 50 mg/l may affect performance if the sulfate or chloride level is high. |

| Sulfate | 25 mg/l | 250 mg/l | Higher levels have laxative effect. Levels above 50 mg/l may affect performance if magnesium and chloride levels are high. |

| Zinc | —- | 1.50 mg/l | Higher levels are toxic. |

| Aluminum (Al) | 5.0 | Fluorine (F) | 2.0 |

| Arsenic (As) | 0.2 | Lead (Pb) | 0.1 |

| Boron (B) | 5.0 | Manganese (Mn) | Off-taste flavor @ 0.05 |

| Cadmium (Cd) | 0.05 | Mercury (Hg) | 0.01 |

| Chromium (Cr) | 1.0 | Nickel (Ni) | 1.0 |

| Cobolt (Co) | 1.0 | Selenium (Se) | 0.05 |

| Copper (Cu) | 0.5 | Zinc (Zn) | 25.0 |

Color, Taste, Odor

Drinking water should be clear, tasteless, odorless, and colorless. As a general observation, a reddish-brown color may indicate the presence of iron, while a blue color indicates the presence of copper. Hydrogen sulfide is indicated by a rotten egg odor. Hydrogen sulfide may also combine with iron to form black water (iron sulfide) that may also implicate the presence of sulfate-reducing bacteria. Taste can be affected by the presence of salts, and a bitter taste is usually associated with the presence of ferrous and manganese sulfates.

Bacteria

The presence of microorganisms is typically a result of surface contamination by organic materials and can result in poor performance. The presence of coliform bacteria is generally related to fecal contamination of drinking water due to runoff to surface or ground waters. Ideally, bacterial contaminants should not be present in drinking water and measurable levels should be zero. Disinfection of the water supply can eliminate bacterial contaminants. Samples taken for bacterial testing should be obtained in a sterile manner and may need to be taken at the source and at strategic points to localize any problems. These sample need to be delivered to a testing facility within 24 hours of the sample being drawn.

pH

The acidity or alkalinity of water is measured by pH. A pH of 7 indicates that the water is neutral, a pH less than 7 indicates acidity, and a pH greater than 7 indicates alkalinity. Low pH water can be unpalatable, corrosive to equipment, and may have a negative impact on performance. High pH water is also unacceptable since it reflects high levels of calcium and magnesium, which can clog watering systems. Poultry accept water on the acid side better than they accept water on the alkaline side. The pH of private wells may vary greatly even in the same county. Municipal water systems tend to have a higher pH up to 9.0 .

Turbidity/Tannins

Turbidity results from the suspension of materials such as silt, clay, algae or organic materials in water. Levels of turbidity above 5 ppm result in unpalatable water and indicate surface contamination. Turbid water can be filtered to remove particular contaminants and prevent clogged water lines. Tannins occur in water in almost any location where large quantities of vegetation have decayed. Tannins can impart a faintly yellowish to brown color to water.

Total Dissolved Solids

Measurement of total dissolved solids (TDS), or salinity, indicates levels of inorganic ions dissolved in water. Calcium, magnesium, and sodium salts are the primary components that contribute to TDS. High levels of TDS are the most commonly found contaminants responsible for causing harmful effects in poultry production. Table 1 provides guidelines suggested by the National Research Council (1974) for the suitability for poultry water with different concentrations of total dissolved solids (TDS), which are the total concentration of all dissolved elements in the water.

Hardness

Hardness refers to the presence of dissolved minerals such as calcium and magnesium in either bicarbonate or sulfate form and is expressed as an equivalent of calcium carbonate. It measures the tendency of water to precipitate soap and form scale. Hard water is commonly associated with the buildup of deposits and the formation of scale in the components of the watering system. Hardness is not commonly harmful to poultry unless certain ions are present in toxic amounts. High levels of magnesium sulfate (MgSO4) may cause an increase in water consumption, wet droppings, and a drop in production. Extreme hardness may diminish the effectiveness of water-administered medications, disinfectants, and cleaning agents.

Nitrogen contamination of water supplies usually occurs in the form of nitrates and nitrites. Both are a result of biological decay of animal or plant matter, chemical fertilizers, or animal wastes. The presence of nitrates often suggests bacterial contamination, since their presence is often a direct result of the seepage of surface water from surrounding fields that were fertilized by either chemicals or animal manures.

Nitrate itself is not toxic. After ingestion, however, it is converted to the toxic form of nitrite by microorganisms found in the intestinal tract of the animal. Once absorbed into the bloodstream, nitrite binds strongly to hemoglobin and, thereby, reduces the oxygen carrying capacity of the blood. Chronic nitrate toxicity causes poor growth, anorexia, and poor coordination. Studies demonstrate that nitrate nitrogen levels in the drinking water as low as 3 to 5 mg/lt depress broiler growth rate.

High concentrations of sulfates can combine with magnesium to form Epsom salt or with sodium salts that cause a laxative effect and can result in wet litter. High concentrations of sodium or chloride may also increase water consumption and increase litter moisture. High levels of sulfate may also interfere with the intestinal absorption of other minerals such as copper.

High levels of magnesium are only a problem in the presence of high sulfate levels since they combine to form Epsom salt. The formation of scale in the watering system can be attributed to high levels of or combinations of sulfate, magnesium, or calcium.

High levels of iron may encourage the growth of bacteria, which can lead to diarrhea. When the ferrous form of iron present in well water is exposed to the air, it is converted to the ferric hydroxide form commonly referred to as rusty water.

Other contaminants in the water may include pesticides, herbicides, industrial residues, petroleum products, and heavy metals such as lead or cadmium. Such contaminants are more difficult to detect and require more costly testing procedures.

Water Treatments

Various methods are available that can reduce or eliminate the impurities that adversely affect water quality. Options include the following.

CHLORINATION. Chlorination is the most common method used to treat water for bacterial contamination and effectively eliminate bacteria from the water supply. Chlorine can be administered through an in-line proportioner. General recommendations are to have a level of 2 to 3 ppm at the drinker farthest from the proportioner. Chlorine levels can be easily monitored using a pool test kit.

Guidelines for Chlorination

Do not chlorinate market age birds under extreme heat stress.

Measure residual chlorine at the waterer to maintain at least a 1.0 ppm level at the drinker mid-house.

Discontinue chlorination and administer powdered milk solution before vaccination to neutralize chlorine since chlorine kills vaccines.

Use caution since chlorine solutions are acidic and often oxidize soft rubber.

SOFTENERS

Use water softening equipment to reduce hardness. Most softening equipment uses ion exchange to effectively remove the calcium and magnesium ions and replace them with sodium ions. Levels of TDS, however, are simply substituted and increases in sodium concentration of the water occur, possibly to unacceptable levels. Poultry are generally sensitive to increases in sodium levels, so producers should be judicial in their selection and use of water softening equipment.

POLYPHOSPHATES

Polyphosphates are chemical compounds used primarily to prevent the buildup of scale in the watering systems. They act to cause mineral contaminants to go into solution more readily.

ELECTRICAL/MAGNETIC DEVICES. Electrical or magnetic devices keep minerals associated with scale buildup in solution by altering their electrical charges.

Water Consumption

Before beginning the discussion of quality, it may be well to consider briefly how much water animals consume. This information might be of some assistance in planning livestock water systems. Water consumption varies over a rather wide range, depending upon a number of physiological and environmental conditions, so that estimates are subject to considerable error. These conditions include the kind and size of animal, whether or not it is lactating, how active it is, the kind and amount of diet it consumes, climatic conditions, and other factors. The usual ranges for water consumption of adult animals has been summarized in Water Quality Criteria, published by the FWPCA in 1968, as follows:

| Water Consumption gallons per day | |

| Chickens | 8-10 per 100 birds |

| Turkeys | 10-15 per 100 birds |

Factors in Water Quality

Most ground or surface waters are satisfactory for livestock. Some are not, however, resulting in poor performance or even death in animals confined to them.

Other Factors. On rare occasions, natural waters may contain or become contaminated with certain toxic elements such as arsenic, mercury, selenium, cadmium, etc., or with radioactive substances. While these may harm animals that drink these waters, our major concern is that they do not accumulate in the meat, milk or eggs making them unsafe for human consumption. Analyses need to be made for these when there is good reason to suspect their presence at excessive levels.

Persistent organic pesticides have been found as contaminants in most surface waters. However, their concentration is so small in these waters (because of their low solubility in water) that they have been found to be no problem to livestock.

Occasionally, heavy algal growths occur in stagnant or slowflowing bodies of water. A few species of these can, under some circumstances, be toxic. We have no tests for these toxins, and at present we can only recommend avoiding using any stagnant source of water for livestock.

Interpreting A Water Analysis

Salinity. A guide to the use of saline waters for livestock is presented in Table I. Considerable judgment should be exercised in using this guide. It has reasonable margins of safety built into it, and adherence to it should prevent deaths or economic losses with rare exceptions.

Nitrates. Comments relating to the use of waters containing nitrates are shown in Table II. In using this table, it is important to take into account the way in which the nitrate content is expressed on the report of analysis. Some express it in parts per million (ppm) of nitrate nitrogen (NO3N). Others express it as parts per million of nitrate (NO3) or of sodium nitrate (NaNO3). The relationship between these various methods of expressing it are as follows:

1 ppm of nitrate nitrogen = 4.43 ppm of nitrate or 6.07 ppm of sodium nitrate. With livestock waters having a total dissolved solids content of less than 1,000 ppm or a conductivity of less than 1,400 micromhos/cm at 25°C, there is no need to make a nitrate determination.

Alkalinity

Waters with alkalinities of less than 1,000 ppm are considered satisfactory for all classes of livestock and poultry. Above that concentration they are probably unsatisfactory, although for adults they may do little harm at concentrations less than about 2,500 ppm unless carbonates are present in excess over bicarbonates.

Miscellaneous

Waters may in some instances supply a portion or even all of an animal’s requirement for certain minerals. As a general rule, however, their contribution with respect to minerals is of no practical significance.

Hard waters have often been suggested as a cause of urinary calculi (kidney stones or water belly). Experimental evidence shows that this is not true, however, and hardness might, in fact, actually contribute to the prevention of certain types of calculi formation.

The results of water analyses have been expressed in a number of ways. Some of these ways and their interrelation are shown below:

One part per million (ppm) means one pound per million pounds of water. For all practical purposes, milligrams per liter (mg/l), milligrams per kilogram (mg/kg), and parts per million (ppm) mean the same thing. One grain per gallon is equivalent to about 17 parts per million.

Highly saline waters are often mistakenly referred to as “alkali” waters.They may or may not be highly alkaline, and usually are not. Sometimes they are referred to as hard waters. If most of their salinity is in the form of sodium salts, however, they may actually be soft waters, as hardness is due largely to calcium and magnesium.

Table I. A Guide to the Use of Saline Water for Livestock and Poultry.

| Total dissolved solids (parts/million)* | Comments |

| Less than 1,000 | From the standpoint of its dissolved solids, this water should be excellent for all classes of livestock. |

| 1,000 to 2,999 | This water should be satisfactory for all classes of livestock. Those waters approaching the upper limit may cause some watery droppings in poultry, but they should not adversely affect the health or production of the birds. |

| 3,000 to 4,999 | This water should be satisfactory for livestock. If not accustomed to it they may refuse to drink it for a few days, but they will adapt to it in time. If sulfate salts predominate, they may show temporary diarrhea, but this should not harm them. It is, however, a poor to unsatisfactory water for poultry. It may cause watery feces, and particularly near the upper limit, it may cause increased mortality and decreased growth, especially in turkey poults. |

| 5,000 to 6,999 | This water can be used for livestock except those that are pregnant or lactating, without seriously affecting their health or productivity. It may have some laxative effects and be refused by the animals until they become accustomed to it. It is unsatisfactory for poultry. |

| 7,000 to 10,000 | This is a poor livestock water that should not be used for poultry or swine. It can be used for older, low-producing ruminants or horses that are not pregnant or lactating with reasonable safety. |

| Over 10.000 | This water is considered unsatisfactory for all classes of livestock. |

* Electrical conductivity expressed in micromhos per centimeter at 25°C can be substituted for total dissolved solids without introducing a great error in interpretation.

Table II. A Guide to the Use of Waters Containing Nitrate for Livestock and Poultry.

| Nitrate content* (ppm nitrate nitrogen) | Comments |

| Less than 100** | Experimental evidence to date indicates that this water should not harm livestock or poultry. |

| 100 to 300 | This water should not by itself harm livestock or poultry. When feeds contain nitrates, this water could add greatly to the nitrate intake to make it dangerous. This could be of some concern in the case of cattle or sheep during drought years and especially with waters containing levels of nitrates that approach the upper limits. |

| Over 300*** | This water could cause typical nitrate poisoning in cattle and sheep, and its use for these animals is not recommended. Because this level of nitrate contributes significantly to salinity and also because experimental work with levels of nitrate nitrogen in excess of this are meager, the use of this water for swine, horses or poultry should also be avoided. |

*Includes nitrite nitrogen.

** Less than 443 ppm of nitrate or less than 607 ppm of sodium nitrate.

*** Over 1,329 ppm of nitrate or over 1,821 ppm of sodium nitrate.

*Adapted from GPE-1401, authored by O.E. Olson and D.G. Fox, South Dakota State University.

Drinking Water Quality for Poultry

Causes of High Bacteria Counts

For more information on well construction and maintenance, request copies of “Rules Governing the Protection of Private Water Supplies,” Section 1700, from the North Carolina Department of Human Resources, Division of Health Services, Environmental Health Section, and “Well Construction Standards Criteria and Standards Applicable to Water Supply and Other Type Wells,” North Carolina Administrative Code, Title 15, subchapter 2C, from the Environmental Management Commission, Environmental Management Division,North Carolina Department of Natural Resources and Community Development.

Controlling Microbial Levels

It is not advisable to use disinfectants to maintain safe bacterial levels in a highly contaminated well. Any disinfectant method is likely to fail at some time and expose the poultry to high levels of bacteria. The only sound approach is to eliminate the source of contamination. If that is not feasible, constructing a new well may be the best alternative.

Even if the water source has a low bacteria level, poultry may be exposed to the microorganisms that grow in waterers. Because these organisms can develop very rapidly, waterers should be cleaned properly each day. Chlorination or use of other disinfectants in the water along with good waterer cleaning is an effective way of controlling microbial levels.

Competition

Chlorination using an in-line proportioner (a device for accurately injecting the correct proportion of chlorine into the water line) has been successful in poultry operations if the residual chlorine level in the waterers is at least 1 milligram per liter (mg/l). Once the water is exposed to the air, however, the dissolved chlorine quickly dissipates. To accurately determine the residual chlorine level in the water that the poultry drink, the chlorine concentration should be measured using a standard test (such as the orthololidine procedure) as soon as possible after samples are obtained from the waterers.

Superchlorination or continuous treatment of the well with chlorine pellets can also be effective, but the level of chlorine in the drinking water must be controlled because excess chlorine will cause poultry to lower their water consumption.

Use of an iodine-base disinfectant to control bacteria in drinking water is effective and provides more residual activity but is usually more expensive than chlorination. Be sure to use only approved chemicals at the recommended rates and ensure that the chemicals are compatible with watering equipment. Also, be sure to remove the disinfectant from the waterers and water lines before using a water vaccine or medication that is incompatible with the disinfectant.

In recent tests of 95 wells used for North Carolina poultry flocks, 16 percent had pH values below 6. Acid drinking water can affect digestion, corrode watering equipment, and be incompatible with medicines and vaccines. Field research indicates that drinking water with a Ph lower than 6 can impair broiler performance. Water with a pH between 6.0 and 6.3 is suspected of having a negative effect.

Hardness

Although hard water may cause stains, leave residues, or cause other physical problems in water-handling equipment, hard water has not been demonstrated to have either a positive or negative impact on poultry performance. In treating hard water that is to be used as drinking water poor poultry, however, care should be taken not to increase any existing chemical imbalance in the water.

Naturally Occurring Chemicals

A large number of chemicals occur naturally in well water. They are usually present in amounts that do not interfere with the metabolism or digestive functions of chickens or turkeys. When the levels of certain chemicals are out of balance, however, they can –by themselves or in combination with other chemicals — affect poultry performance.

Sodium. Excessive levels of sodium (Na) have a diuretic effect. The normal sodium level in water is about 32 mg/l. Studies indicate that a sodium level of 50 mg/l is detrimental to broiler performance if the sulfate level is also 50 mg/l or higher and the chloride level is 14 mg/l or higher.

Chloride. Consuming too much chloride (Cl) has a detrimental effect on metabolism. A chloride level of 14 mg/l is considered normal for well water. Studies have shown that a level of 14 mg/l in drinking water can be detrimental to broilers if combined with 50 mg/l of sodium. Chloride levels as high as 25 mg/l are not a problem if the sodium level is in the normal range.

Sulfate. High sulfate (SO4) levels have a laxative effect. Levels of about 125 mg/l are regarded as normal for well water, but levels as low as 50 mg/l can have a negative effect on performance of either the sodium or magnesium level is 50 mg/l or more.

Magnesium. A symptom of a high magnesium (Mg) level is loose droppings. The normal level of magnesium in well water is about 14 mg/l. This chemical may interact with sulfate. Studies indicate that magnesium alone at 68 mg/l does not adversely affect broiler performance, but a level of 50 mg/l can be detrimental if the sulfate level is also 50 mg/l or greater.

Other Chemicals. Excessively high or low concentrations of other chemicals can produce recognizable symptoms. Excessive amounts of manganese (Mn) can produce a flavor problem. Too much copper (Cu) can give the water a bitter taste and may cause liver damage. High phosphate (PO4) levels may indicate contamination from sewage. Calcium (Ca) does not seem to have any negative effect at levels as high as 400 mg/l, and it appears that a level of 35 mg/l or more may be desirable. High levels of iron (Fe) — up to 25 mg/l — have not been shown to be detrimental to broiler performance, although staining of waterers is evident at much lower levels. Guidelines for levels of iron, lead (Pb), and zinc (An) in drinking water are listed in Table 1.

Taking a Water Sample

The results of a water analysis will be reliable only if the samples are taken correctly. Your county health department will probably be willing to work with you in obtaining water samples and having them tested for bacteria and chemicals in the State Health Department laboratories. Commercial laboratories will also perform water tests for a fee. Be sure to specifically request that your samples be tested for the chemicals and other factors that can be detrimental to poultry production as well as for the presence of microorganisms.

When you collect samples, remember that the water should first be allowed to run for several minutes to allow a representative fresh sample to reach the water outlet. The outlet should than be sterilized by flaming or other suitable method, and the sample should be placed in a sterilized container. The sample should arrive at the testing laboratory within 24 hours if bacteria tests are to be accurate.

Correcting Water Problems

If you are faced with a water quality problem, treating the water may help. It is best to give first priority, however, to finding the underlying cause for poor water quality and correcting the problem if possible. In some cases it may be necessary to find a different source of water.

For more information about water quality, ask your county Extension agent for a Copy of Water Quality Control by Ronald E. Sneed, Extension Biological and Agricultural Engineering Specialist.

Prepared by

Thomas A. Carter, Specialist in Charge, Extension Poultry Specialist and

Ronald E. Sneed, Extension Biological and Agricultural Engineering Specialist

Appreciation is expressed to Charles Brewer and Michael Wineland, Extension Poultry Specialists, for their assistance in collecting data in support of the information presented.

For further information, contact your county Extension agent or Extension Poultry Science, Campus Box 7608, N.C. State University, Raleigh, NC 27695-7608

North Carolina State University

Drinking Water Quality for Poultry

Prepared by:

Thomas A. Carter

Specialist in Charge

Extension Poultry Science

Ronald E. Sneed

Extension Biological and Agricultural Engineering Specialist

Published by: North Carolina Cooperative Extension Service

Publication Number: PS&T #42

Last Electronic Revision: March 1996 (JWM)

Water is involved in every aspect of poultry metabolism. It plays important roles in regulating body temperature, digesting food, and eliminating body wastes. At normal temperatures, poultry consume at least twice as much water as feed. When heat stress occurs, water consumption will double or quadruple. A safe and adequate supply of water is therefore essential for efficient poultry production.

What are the characteristics of safe, good-quality drinking water for poultry? The answer to this question is often complex because the quality of drinking water can be evaluated in a number of ways. It can be tested for the presence of bacteria and other microbes, for the levels of minerals that occur naturally in the water, and for other chemical and physical factors. This guide describes the most useful indicators of water quality and tells how to take a water sample correctly to ensure accurate test results.

Interpreting Bacteria Test Results

If the number of microorganisms found in a water sample is too high, it indicates that the water supply is contaminated. Well water is normally tested for the total bacteria level, the coliform bacteria level, and occasionally for the fecal coliform bacteria level. Coliform bacteria are organisms normally found in the digestive tracts of livestock, humans, and birds. Their presence in water is used as a sign of fecal contamination.

Standards for animal drinking water indicate that there should be fewer than 100 bacteria of all types per milliliter (ml) of water and fewer than 50 coliform bacteria per ml (see Table 1). Recent field research indicates that a bacteria level of zero may be desirable to obtain optimum performance.

Causes of High Bacteria Counts

High bacteria counts in well water may be due to contamination from sources such as sewage treatment fields that are poorly designed, improperly constructed, failing, or located too close to the well. High counts may also result from poor well construction (particularly in the case of old or shallow wells) or poor maintenance if the well is not properly protected from surface drainage water.

For more information on well construction and maintenance, request copies of “Rules Governing the Protection of Private Water Supplies,” Section 1700, from the North Carolina Department of Human Resources, Division of Health Services, Environmental Health Section, and “Well Construction Standards Criteria and Standards Applicable to Water Supply and Other Type Wells,” North Carolina Administrative Code, Title 1S, subchapter 2C, from the Environmental Management Commission, Environmental Management Division, North Carolina Department of Natural Resources and Community Development.

Controlling Microbial Levels

It is not advisable to use disinfectants to maintain safe bacterial levels in a highly contaminated well. Any disinfectant method is likely to fail at some time and expose the poultry to high levels of bacteria. The only sound approach is to eliminate the source of contamination. If that is not feasible, constructing a new well may be the best alternative.

Even if the water source has a low bacteria level, poultry may be exposed to the microorganisms that grow in waterers. Because these organisms can develop very rapidly, waterers should be cleaned properly each day. Chlorination or use of other disinfectants in the water along with good waterer cleaning is an effective way of controlling microbial levels.

Chlorination using an in-line proportioner (a device for accurately injecting the correct proportion of chlorine into the water line) has been successful in poultry operations if the residual chlorine level in the waterers is at least 1 milligram per liter (mg/l). Once the water is exposed to the air, however, the dissolved chlorine quickly dissipates. To accurately determine the residual chlorine level in the water that the poultry drink, the chlorine concentration should be measured using a standard test (such as the orthololidine procedure) as soon as possible after samples are obtained from the waterers. Superchlorination or continuous treatment of the well with chlorine pellets can also be effective, but the level of chlorine in the drinking water must be controlled because excess chlorine will cause poultry to lower their water consumption.

Use of an iodine-base disinfectant to control bacteria in drinking water is effective and provides more residual activity but is usually more expensive than chlorination. Be sure to use only approved chemicals at the recommended rates and ensure that the chemicals are compatible with watering equipment. Also, be sure to remove the disinfectant from the waterers and water lines before using a water vac- cine or medication that is incompatible with the disinfectant.

Nitrates and Nitrites

Nitrates (NO3) are produced during the final stage of decomposition of organic matter. Their presence in water usually indicates contamination by runoff containing fertilizer or human and animal wastes. Nitrates are soluble and may move with surface runoff or leach into the groundwater by percolation through the soil. Nitrates from sources such as animal and human wastes, nitrogen fertilizer, crop residues, and industrial wastes may move considerable distances in the ground. Nitrite (NO2) is produced during intermediate stages of the decomposition of organic compounds.

Table 1. Drinking Water Quality Guidelines

Contaminant or Level Maximum Remarks

characteristic considered acceptable

average level

Bacteria

Total bacteria…………………. 0/ml 100/ml 0/ml is desirable.

Coliform bacteria………………. 0/ml 50/ml 0/ml is desirable.

Nitrogen Compounds

Nitrate ……………………. 10 mg/l 25 mg/l Levels from 3 to 20 mg/l may affect

performance.

Nitrite …………………… 0.4 mg/l 4 mg/l

Acidity and Hardness

pH ………………………… 6.8-7.5 …… A pH of less than 6.0 is not desirable.

Levels below 6.3 may degrade

performance.

Total hardness………………. 60-180 …… Hardness levels less than 60 are

unusually soft, those above 180, very

hard.

Naturally Occurring Chemicals

Calcium ……………………. 60 mg/l ……

Chloride …………………… 14 mg/l 250 mg/l Levels as low as 14 mg/l may be

detrimental if the sodium level is

higher than 50 mg/l.

Copper ………………….. 0.002 mg/l 0.6 mg/l Higher levels produce a bitter flavor.

Iron ……………………… 0.2 mg/l 0.3 mg/l Higher levels produce a bad odor and

taste.

Lead ……………………… ……. 0.02 mg/l Higher levels are toxic.

Magnesium ………………….. 14 mg/l 125 mg/l Higher levels have a laxative effect.

Levels greater than 50 mg/l may affect

performance if the sulfate level is

high.

Sodium …………………….. 32 mg/l …… Levels above 50 mg/l may affect per-

formance if the sulfate or chloride

level is high.

Sulfate …………………… 125 mg/l 250 mg/l Higher levels have a laxative effect.

Levels above 50 mg/l may affect per-

formance if magnesium and chloride

levels are high.

Zinc …………………….. 1.50 mg/l Higher levels are toxic.

Source: Schwartz, D. L., “Water Quality,” VSE, 81c., Penn. State Univ. (mimeographed); and R. Waggoner, R. Good, and R. Good, “Water Quality and Poultry Pedormance,” in Proceedings AVMA Annua/ Conference, July, 1984.

The toxicity of nitrates to poultry varies with the age of the birds, older birds being more tolerant. Levels in excess of 50 mgA for chickens and 75 mgA for turkeys have proven harmful in laboratory trials. A recent study with commercial broilers showed that nitrate levels greater than 20 mgA had a negative effect on weight, feed conversion, or performance. Levels between 3 and 20 mgA were suspected to affect performance. Nitrites are toxic at much lower levels than nitrates; concentrations as low as 1 mgA can be toxic.

Well-drilling techniques have improved since many of the older, shallow wells were constructed. If nitrate or nitrite levels in your well water are too high and you cannot eliminate the source of contamination, drilling a new or deeper, properly constructed well may solve the problem.

Acidity and Alkalinity

The acidity or alkalinity of water is expressed as its pH level. Neutral water (that which is neither acid nor alkaline) has a pH of 7. Acidic water has a pH lower than 7 and alkaline water has a pH greater than 7. Well water normally has a pH in the range from 6.8 to 7.8, although it is not uncommon for the pH to be either higher or lower.*

In recent tests of 95 wells used for North Carolina poultry flocks,16 percent had pH values below 6. Acid drinking water can affect digestion, corrode watering equipment, and be incompatible with medicines and vaccines. Field research indicates that drinking water with a pH lower than 6 can impair broiler performance. Water with a pH between 6.0 and 6.3 is suspected of having a negative effect.

* In this publication the values that are given as “normal” are representative of those that one might expect to find in water used for drinking. They are not intended as averages or desirable target values.

Hardness

Although hard water may cause stains, leave residues, or cause other physical problems in water-handling equipment, hard water has not been demonstrated to have either a positive or negative impact on poultry performance. In treating hard water that is to be used as drinking water for poultry, however, care should be taken not to increase any existing chemical imbalance in the water.

Naturally Occurring Chemicals

A large number of chemicals occur naturally in well water. They are usually present in amounts that do not interfere with the metabolism or digestive funtions of chickens or turkeys. When the levels of certain chemicals are out of balance, however, they can – by themselves or in combination with other chemicals – affect poultry performance.

Sodium. Excessive levels of sodium (Na) have a diuretic effect. The normal sodium level in water is about 32 mgA. Studies indicate that a sodium level of 50 mgA is detrimental to broiler performance if the sulfate level is also 50 mgA or higher and the chloride level is 14 mgA or higher.

Chloride. Consuming too much chloride (Cl) has a detrimental effect on metabolism. A chloride level of 14 mgA is considered normal for well water. Studies have shown that a level of 14 mgA in drinking water can be detrimental to broilers if combined with 50 mgA of sodium. Chloride levels as high as 25 mgA are not a problem if the sodium level is in the normal range.

Sulfate. High sulfate (S04) levels have a laxative effect. Levels of about 125 mgA are regarded as normal for well water, but levels as low as 50 mgA can have a negative effect on performance if either the sodium or magnesium level is 50 mgA or more.

Magnesium. A symptom of a high magnesium (Mg) level is loose droppings. The normal level of magnesium in well water is about 14 mgA. This chemical may interact with sulfate. Studies indicate that magnesium alone at 68 mgA does not adversely affect broiler performance, but a level of 50 mgA can be detrimental if the sulfate level is also 50 mgA or greater.

Other Chemicals. Excessively high or low concentrations of other chemicals can produce recognizable symptoms. Excessive amounts of manganese (Mn) can produce a flavor problem. Too much copper (Cu) can give the water a bitter taste and may cause liver damage. High phosphate (P04) levels may indicate contamination from sewage. Calcium (Ca) does not seem to have any negative effect at levels as high as 400 mgA, and it appears that a level of 35 mgA or more may be desirable. High levels of iron (Fe) – up to 25 mg/l – have not been shown to be detrimental to broiler performance, although staining of waterers is evident at much lower levels. Guidelines for levels of iron, lead (Pb), and zinc (Zn) in drinking water are listed in Table 1.

Taking a Water Sample

The results of a water analysis will be reliable only if the samples are taken correctly. Your county health department will probably be willing to work with you in obtaining water samples and having them tested for bacteria and chemicals in the State Health Department laboratories. Commercial laboratories will also perform water tests for a fee. Be sure to specifically request that your samples be tested for the chemicals and other factors that can be detrimental to poultry production as well as for the presence of microorganisms .

When you collect samples, remember that the water should first be allowed to run for several minutes to allow a representative fresh sample to reach the water outlet. The outlet should then be sterilized by flaming or other suitable method, and the sample should be placed in a sterilized container. The sample should arrive at the testing laboratory within 24 hours if bacteria tests are to be accurate.

Correcting Water Problems

If you are faced with a water quality problem, treating the water may help. It is best to give first priority, however, to finding the underlying cause for poor water quality and correcting the problem if possible. In some cases it may be necessary to find a different source of water.

For more information about water quality, ask your county Extension agent for a copy of Water Quality Control by Ronald E. Sneed, Extension Biological and Agricultural Engineering Specialist.

Distributed in furtherance of the Acts of Congress of May 8 and June 30, 1914. Employment and program opportunities are offered to all people regardless of race, color, national origin, sex, age, or disability. North Carolina State University, North Carolina A&T State University, U.S. Department of Agriculture, and local governments cooperating.

Water is a critical nutrient that receives little attention until a problem arises. Not only should producers make an effort to provide water in adequate quantity, they should also know what is in the water to be used in evaporative cooling systems and consumed by the birds.

| Figure 1. |

Functions of Water

Poultry producers need water for birds to drink, to reduce air temperature (includes evaporative cooling pad and fogging systems), and to clean and sanitize the facility. Broilers consume approximately 1.6 to 2.0 times as much water on a weight basis as feed. Water is a critical nutrient in bird metabolism and nutrition. From a physiology perspective, water consumed by the bird is used for nutrient transportation, enzymatic and chemical reactions in the body, body temperature regulation, and lubrication of joints and organs.

There is a strong relationship between feed and water consumption, so water can be used to monitor flock performance. Many of the electronic controllers in poultry houses have the ability to monitor daily water consumption. A potential problem may exist if there is a sudden change in water intake. Bird uniformity between the front and back of the house can be monitored using water consumption. Water consumption will be greater in the area of the house that has more birds. When birds are not distributed evenly between the front and back of the house, increased competition for feed and water space and can reduce bird performance.

Factors Affecting Water Consumption

Several factors affect water consumption:

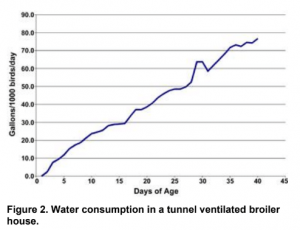

Bird Age: Water consumption increases with age but decreases as a percentage of body weight.

| Figure 2. Water consumption in a tunnel ventilated broiler house. |

Environmental Temperature/Heat Stress: Birds consume more water as temperature increases. One of the main ways birds regulate body temperature is to remove heat from the body by evaporating water through the respiratory system during panting. As birds pant, water is lost and needs to be replaced in order to maintain body water balance. Water consumption can double and even triple during periods of heat stress. Water consumption in broilers increases approximately 7 percent for each degree Fahrenheit increase in temperature. A study at the University of Georgia examined the relationship of feed consumption to water consumption of seven consecutive flocks on a commercial broiler farm. As temperatures increased, the water consumed per pound of feed consumed also increased (Table 1).

| Table 1. Water consumption response to different weather conditions. | |

| lb of water per lb of feed | |

| Cold weather | 1.55 |

| Mild weather | 1.65 |

| Hot weather | 1.75 |

Water Temperature: Several studies have examined the effects of providing cool water to birds during hot weather. In most of these studies, water temperature has improved the performance of broilers and layers. Any water temperature below the body temperature of the bird will be beneficial. The water consumed will help dissipate body heat temperature. In commercial operations, however, air speed is the most effective way to keep birds cool. Water is difficult to cool significantly and economically when it is moving hundreds of feet down a house.

Electrolytes: During periods of potential heat stress, many producers supplement drinking water with electrolytes. Electrolytes are certain minerals that can be found in the blood and are important for normal cell function and growth. Electrolytes, as the name implies, help regulate nerve and muscle function by conducting electrical signals from nerves to muscles. Electrolytes are also important for the acid-base balance of the blood and fluid retention. Some of the electrolytes found in blood plasma include sodium (Na), potassium (K), calcium (Ca), magnesium (Mg), chlorine (Cl), bicarbonate (HCO3) and sulfate (SO4). The addition of the electrolytes not only replenishes those depleted during heat stress, it also stimulates water consumption. When the results of these are added together (electrolytes and increased water consumption), the mortality due to heat stress can be reduced.

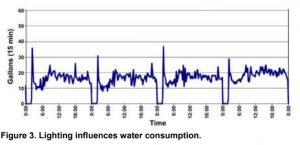

Lighting Programs: Light is another environmental factor that can influence bird water consumption. In operations that use lighting programs, two distinct water consumption peaks can be observed. The first peak is just after the lights come on (dawn), and the second is just prior to lights turning off (dusk). In Figure 3, the water consumption actually starts to drop about an hour prior to the lights turning off. This indicates that the birds are anticipating the upcoming dark period and activity in the house has already begun to decline.

| Figure 3. Lighting influences water consumption. |

The correlation of water consumption with feed intake and many environmental factors indicate its importance in bird metabolism and body function. Efforts should be made in all poultry operations to ensure that adequate and unlimited access to water is provided. Failure in doing so will result in poor egg production, reduced growth, and reduced feed efficiency.

Water Quality

While water is composed of hydrogen and oxygen molecules (H2O), it is a universal solvent and can contain many minerals and compounds. The only sure way to get pure water is to use distillation or other treatment methods to remove dissolved minerals and compounds. While we do not need pure water for poultry drinking water, we do not want heavily contaminated water either. Water composition varies with geographical region as the nature of the geological makeup changes. Water contamination can occur if surface water drains into the well. All farms should submit water samples to a qualified laboratory for testing to establish a baseline for water quality. This will help producers determine if and what water treatment might be warranted.

All poultry operations should be concerned about water quality. Poor water quality may interfere with digestion and subsequent bird performance. The effectiveness of vaccines and medications administered through the water lines could be reduced when water quality is poor. Water contaminants could create equipment problems that would either restrict the amount of water available for consumption or affect the evaporative cooling and fogging systems. Reduced water consumption or cooling capacity would have detrimental effects on both growth and reproduction.

Poor water quality could also cause leaky water nipples inside the house, which will wet litter and lead to increased ammonia production. Poor litter quality and high levels of ammonia can cause reduced performance and livability.

Standards for water quality should include factors that affect taste, solid buildup within water systems, and toxicity. Factors that should be observed for poultry production include, but are not limited to:

| Color: | Water is colorless, and any color in the water may indicate an increased contamination level. |

| Turbidity: | Particles such as clay, silt, sand or organic matter in suspension can cause the water to appear cloudy or muddy. Turbid water can cause leaky nipples and clog fogging nozzles. |

| Hardness: | Calcium and magnesium salts cause the water to be “hard” and can lead to scale and sludge buildup within water lines. Hardness reduces the effectiveness of soaps and disinfectants and interferes with the administration of some medications. |

| Iron (Fe): | Iron will stain almost everything it contacts, and it is a common water quality issue. Recent studies indicate that iron in the water does not appear to affect poultry health, but some of the iron may form solid particulates such as iron oxide, which can lead to equipment problems. These small particles can cause leaky nipples and block fogging nozzle openings. Either of these conditions can have negative impacts on poultry production. Iron bacteria are more likely to thrive in water with high iron concentrations. As a result, biofilm buildup can occur, which can obstruct nipple drinkers and promote pathogen proliferation. |

| Manganese (Mg): | While manganese itself does not cause a negative effect on poultry health, like iron, it can form solid particulates that can cause leaky nipples and clog foggers. |

| Nitrate-N (N): | Elevated nitrate concentrations indicate decaying organic material. It has been correlated with poor oxygen use in animals, but recent studies observed no differences in broiler performance with nitrate levels as high as 600 ppm. Presence of nitrate is a good indicator that water should be checked for bacteria. |

| pH: | The pH is a measure of acidity or alkalinity. A scale from 0-14 is used to measure pH. A value of 7.0 is neutral, values below 7.0 are acidic and values greater than 7.0 are basic. A pH of 6.0 to 6.8 is preferred for broiler production, but birds can tolerate a pH range of 4 to 8. A pH range of greater than 8 could cause reduced water consumption. |

| Alkalinity: | Caused by calcium carbonate, bicarbonate or sulfate. High alkalinity increases the buffering capacity of water. |

| Total solids: | Total solids represent the total amount of solid material in both suspension and solution. Total solids are not directly linked to any poultry health issues, but equipment function and water delivery could be nega-tively affected by total solids, which could influence bird performance. |

| Toxic compounds: | The amount will vary depending on the compound, but elements such as lead, selenium and arsenic should be kept below 1.0 ppm to prevent bird health problems as well as residues. |

| Dissolved oxygen: | Normal ground water concentrations have little or no dissolved oxygen. Concentrations greater than zero indicate possible surface water influence. |

| Bacteria: | Keep bacteria levels to a minimum (Table 2). |

| Table 2. Use the following table as a guide for drinking water quality for poultry. | ||

| Contaminant, Characteristic or Mineral | Maximum Acceptable Levels | |

| Bacteria | ||

| Total Heterotrophic Bacteria | 100 CFU/100 ml | |

| Coliform Bacteria | 50 CFU/100 ml | |

| pH | 6.0 – 8.0 | |

| Hardness | 110 ppm | |

| Naturally Occurring Compounds | ||

| Calcium | 500 ppm | |

| Chloride | 250 ppm | |

| Copper | 0.6 ppm | |

| Iron* | 0.03 ppm | |

| Magnesium | 125 ppm | |

| Manganese** | 0.05 ppm | |

| Nitrate*** | 25 ppm | |

| Phosphorus | 0.1 ppm | |

| Potassium | 500 ppm | |

| Sodium | 50 ppm | |

| Sulfate | 250 ppm | |

| *Iron as high as 660 ppm has been shown to not affect bird health, but it will have detrimental effects on water lines and fogging systems (Fairchild et al., 2005). **Manganese as high as 20 ppm has been reported to not affect bird health, but it can have negative effects on water lines and fogging systems (Batal et al., 2005). ***Nitrates as high as 600 ppm have been shown to not affect bird health (unpublished data). | ||

Many of the water quality standards for poultry drinking water were originally developed from those for human drinking water. Few of the standards recommended today are based on research utilizing broiler or layers. Recently, a series of studies has been conducted examining the effects of iron (Fe), manganese (Mn), nitrates (NO3) and pH levels in drinking water on poultry performance. The results of these studies have found that very high levels of Fe, Mn and NO3 do not impact broiler health. In those studies no differences in performance were noted due to 600 ppm of Fe, 600 ppm of NO3 and 20 ppm of Mn. It should be noted that the water lines were thoroughly flushed between studies and that particulates that result from high Fe and Mn levels can lead to equipment problems such as leaky nipples and clogged fogging nozzles. These studies tested each contaminant individually, and combinations of various contaminants at increased concentrations may still impact broiler performance. When birds are experiencing problems such as feed passage or poor feed conversion, however, broiler performance is more likely to be affected by improper equipment function rather than bird health due to high concentrations of these substances. Poor water quality can lead to increased microbial growth (such as iron bacteria) and biofilm buildup.

Water Management Tips

- Conduct water tests.

Each farm should have its well water tested. Water quality can change during periods of heavy rain or drought, and additional water tests during these periods will ensure that water lines continue to deliver adequate water volume for both the birds and the cooling systems. County extension agents can provide more information on the tests available, provide information on fees for testing, and submit samples to the Agricultural and Environmental Services Laboratory at the University of Georgia. - Change filters regularly.

Sediment and other particulates can cause leaky water nipples that can have negative effects on litter quality. Clogged filters restrict water flow to the drinker and cooling systems. In some cases, simple cartridge filters may not be adequate, such as for water with high iron. In those cases, consider other water treatments. - Flush water lines regularly.

Perform a high pressure flush on water lines between each flock and after adding supplements through the medicator (i.e., vaccine, medications, vitamins, electrolytes, etc.). - Plan ahead before treating water.

Before implementing water treatment or sanitation programs, consult your county agent to be sure contaminants in your water will not react negatively and cause the water system to become clogged.

Get in touch

Are you ready for a Quote on your Project? Please fill out the following fields to request a quote, get more information or submit a testimonial..

Why Intec America?

Developed by NASA

Intec was the first to commercialize the NASA related research on the ionization technology

Value

Ionization is least expensive alternative for maintaining your pool or spa.

Eco-Friendly

Ionization is chemical free and chlorine free. Intec offers many technologies that are healthier for your family and better for the environment.

Experience

Intec has been offering new and innovative technologies to market for over 45 years.